Quality control to ensure safe silicone bras is essential for maintaining product safety, comfort, and durability. This article systematically covers Xinke’s quality control framework, material verification, in-process monitoring, critical adhesion and durability testing, final inspection, defect prevention, and continuous improvement practices.

Xinke’s Quality Control Framework: Standards and Certifications Ensuring Safe Silicone Bras

Xinke follows a precise Silicone Bra Manufacturing Process in the Factory that ensures high product quality and safety. This process involves careful selection of medical-grade silicone and adhesives, controlled molding, adhesive application, curing, trimming, and thorough inspections at every stage. If you want to learn more about the detailed manufacturing steps, you can click “Silicone Bra Manufacturing Process in the Factory” for full information.

At the core of Xinke’s operations is a robust quality management system based on internationally recognized standards, including ISO 9001 and BSCI certifications. These standards establish strict protocols for material verification, process control, and final product inspection. Adhering to such frameworks is crucial for maintaining consistent product quality and ensuring that silicone bras are safe for prolonged skin contact.

Implementing these quality standards not only helps prevent defects and contamination but also builds customer trust by guaranteeing product safety and durability. This systematic approach enables Xinke to deliver silicone bras that meet global regulatory requirements and consumer expectations.

Material Quality Verification: Medical‑Grade Silicone and Adhesive Safety Checks

To begin with, material quality verification is a crucial step in ensuring the safety and performance of silicone bras.

Silicone Material Quality Verification

Xinke sources medical-grade silicone that complies with FDA and REACH standards, ensuring biocompatibility and absence of harmful substances. Incoming silicone undergoes physical and chemical testing, including viscosity measurement, elasticity checks, and contaminant screening. These inspections ensure that the silicone meets required safety and performance criteria, reducing the risk of skin irritation or allergic reactions. Verifying material quality also guarantees consistent texture and durability, essential for long-lasting adhesive bras.

Adhesive Material Verification

Adhesive quality directly impacts the product’s stickiness and user safety. Xinke uses adhesives certified to meet ISO 10993 biological evaluation standards, ensuring hypoallergenic and non-toxic properties. Adhesive batches are tested for tack strength, uniformity, and chemical stability under various environmental conditions. Proper adhesive verification prevents early peeling, maintains wearability, and avoids adverse skin reactions. Ensuring high adhesive quality aligns with regulatory requirements and enhances customer satisfaction.

Other Materials and Quality Control Processes

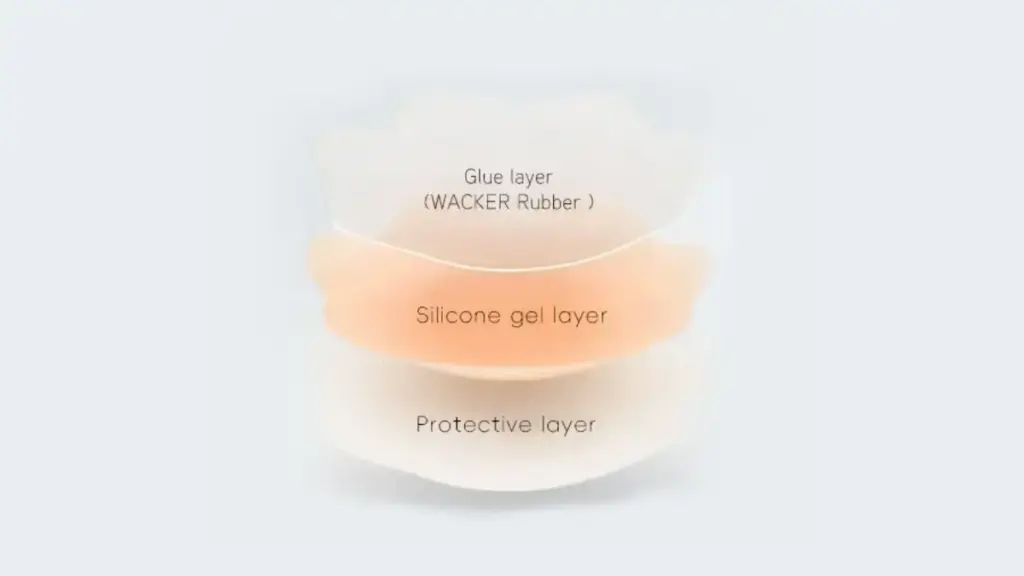

Apart from silicone and adhesives, other materials such as protective films, packaging components, and release liners are also subject to strict quality control. Protective films are inspected for purity and barrier properties to maintain adhesive effectiveness. Packaging materials must meet hygiene standards to prevent contamination and comply with labeling regulations. Each material batch undergoes supplier audits and random sampling tests to ensure consistent quality throughout the manufacturing cycle. This comprehensive control system supports product safety and regulatory compliance across all components.

In‑Process Quality Monitoring: Controlling Each Manufacturing Stage for Consistency

To maintain consistent quality throughout the production process, in-process quality monitoring plays a crucial role in controlling each manufacturing stage.

Mold Preparation and Silicone Injection Monitoring

Mold preparation is the foundational step in the silicone bra manufacturing process and requires stringent quality control to ensure product consistency. Xinke performs detailed inspections of molds to verify cleanliness, dimensional accuracy, and surface integrity before each production run. During silicone injection, process parameters such as temperature, injection pressure, and timing are continuously monitored using automated control systems. This ensures uniform silicone distribution and prevents defects like air bubbles or uneven thickness, which can compromise product safety and comfort.

Adhesive Application and Curing Control

Adhesive application is critical for the bra’s functionality and wearer comfort. Xinke uses calibrated brushing equipment to apply adhesive with precision and consistency. Real-time thickness measurements and uniformity checks are conducted throughout this stage. Curing parameters such as temperature and duration are strictly controlled to achieve optimal adhesive bonding without degrading material properties. Monitoring these variables minimizes risks of delamination or premature adhesive failure, which are essential for safe silicone bras.

Visual and Dimensional Inspections During Production

At key production intervals, Xinke employs both manual and automated visual inspections to detect surface defects such as bubbles, contamination, or uneven edges. Dimensional measurements verify that the silicone bras meet strict tolerances for shape and size, ensuring product uniformity and fit. Defective products are immediately segregated to prevent further processing, supporting overall process reliability and product safety.

Hygiene and Contamination Control

Due to the intimate skin contact nature of silicone bras, contamination control is a critical in-process quality factor. Xinke enforces cleanroom conditions, requiring operators to wear protective gear and follow standardized sanitation procedures. Production areas undergo routine cleaning, and microbial contamination tests are regularly performed on surfaces and tools to prevent product contamination and ensure wearer safety.

Together, these in-process quality monitoring steps form the backbone of Xinke’s quality control system, enabling consistent production of safe, high-performance silicone bras.

Adhesion and Durability Testing: Ensuring Long‑Lasting Performance and Skin Safety

Adhesion and durability testing are essential to ensure that silicone bras perform reliably and remain safe over time. Xinke conducts several key tests to guarantee high product standards:

- Adhesion Strength Tests:

Peel tests and shear tests are conducted to evaluate the bond strength between the silicone and adhesive. These tests measure the force required to separate the adhesive from the silicone, ensuring it stays intact under normal wear and tear.

- Durability Testing:

Prolonged use is simulated through stretching, washing, and exposure to various environmental factors like sweat and oils. This helps assess whether the adhesive and silicone withstand regular wear without degradation.

- Resistance to Moisture and Oils:

Xinke evaluates how well the silicone bras resist sweat, body oils, and moisture, ensuring that the adhesive does not lose its effectiveness over time, even in challenging conditions.

- Skin Compatibility Tests:

Adhering to ISO 10993 biological evaluations, Xinke ensures that the materials used in the silicone bras do not cause irritation or allergic reactions, making them safe for long-term skin contact.

By performing these rigorous tests, Xinke ensures that its silicone bras offer long-lasting performance and skin safety for consumers, building trust and reliability.

Final Inspection and Hygienic Packaging: Preventing Defects Before Market Release

The final inspection and packaging stages are critical to maintaining the quality and safety of silicone bras before they are released to the market:

- Visual and Dimensional Inspections:

A thorough visual inspection is conducted to detect defects such as air bubbles, adhesive inconsistencies, or surface irregularities. Additionally, dimensional checks ensure the product meets size specifications, providing a consistent fit and comfort.

- Functional Testing:

Elasticity and adhesive strength are tested to verify that the silicone bras perform well under everyday wear, maintaining comfort and support over time.

- Batch Traceability:

Each finished product is linked to its raw materials and production date, ensuring full traceability and accountability in case of any post-production issues.

- Sterile Packaging and Protective Films:

Silicone bras are packaged in sterile conditions to prevent contamination during transport. Protective films are applied to safeguard the adhesive surfaces from damage before reaching the consumer.

- Compliance with Packaging Standards:

Packaging materials are carefully selected to meet international safety standards. This ensures the products remain free from contamination and comply with regulatory labeling requirements.

Through these detailed final inspections and hygienic packaging practices, Xinke guarantees that its silicone bras are defect-free and ready for safe, high-quality market release.

Common Defects Detected and Preventive Measures in Xinke’s QC System

Xinke’s QC system is designed to detect and address common defects in silicone bras, ensuring product quality and safety. Here are a few common issues and the preventive measures taken:

- Air Bubbles:

Air bubbles can weaken the structural integrity of the silicone bras. Xinke prevents this by using advanced degassing techniques during silicone injection and ensuring consistent temperature control in the molding process.

- Uneven Adhesive Distribution:

Uneven application of adhesive can lead to premature peeling. To address this, Xinke uses calibrated brushing equipment and performs real-time thickness measurements to ensure even coverage throughout production.

- Surface Imperfections:

Surface defects like rough edges or contaminants can affect both aesthetics and wearability. Xinke utilizes visual inspections and ultrasonic testing to detect and remove defective pieces before they proceed to the next production stage.

- Dimensional Inconsistencies:

Dimensional errors may result in poor fit or comfort. Xinke conducts automated dimensional checks to ensure that all silicone bras meet precise size and shape specifications.

By proactively detecting and addressing these defects, Xinke maintains high-quality standards and ensures safe, reliable products for consumers.

Continuous Quality Improvement: Audits, Training, and 5S Management at Xinke

Xinke’s commitment to continuous quality improvement is embedded in its daily operations. The company rigorously follows ISO 9001 and BSCI standards, ensuring adherence to global quality and social compliance frameworks. Regular internal and external audits are conducted to identify process inefficiencies and implement corrective actions.

To foster quality awareness, Xinke invests in employee training, ensuring that all staff members are well-equipped to detect and address potential issues. Training sessions are updated periodically to keep pace with industry developments.

Xinke also applies the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain), creating an organized, efficient workspace that minimizes errors and enhances productivity. This holistic approach strengthens the company’s commitment to quality and continuous improvement.

This ongoing dedication to quality ensures that Xinke’s silicone bras consistently meet the highest safety and performance standards. For more detailed insights into Xinke’s manufacturing and quality control processes, visit our website or contact us directly to learn how we can support your product needs.